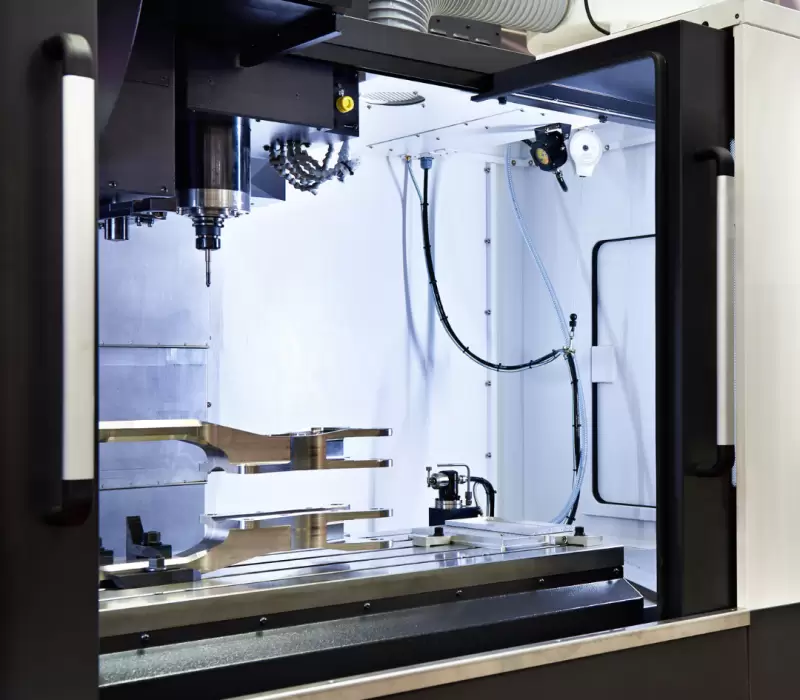

Combining CNC Machining and 3D Printing

In today’s competitive business environment, reducing time-to-market is crucial for companies aiming to stay ahead. Leveraging rapid prototyping technologies like 3D printing and CNC machining, businesses can speed up product development and achieve faster market entry.

This article explores the strategies and technologies that help businesses accelerate product development and minimize delays.

What is Hybrid Manufacturing?

Hybrid manufacturing refers to the integration of subtractive (CNC machining) and additive (3D printing) technologies into a unified production process. By blending the strengths of both methods, manufacturers can streamline the production cycle, reduce waste, and create complex parts with enhanced precision.

Key Benefits of Hybrid Manufacturing

- 3D printing allows for intricate designs and geometries that traditional methods struggle to produce. Whether it’s internal channels, lattice structures, or complex surfaces, additive manufacturing gives you the freedom to innovate.

- Once the base structure is printed, CNC machining takes over to finish the part with ultra-precise features, such as smooth surfaces, fine tolerances, and exact dimensions.

Using hybrid manufacturing, you can cut down on multiple separate production processes. Instead of creating parts in various stages, 3D printing can quickly produce a near-complete model, which is then finished by CNC machining. This approach saves valuable time, especially for rapid prototyping or custom low-volume production.

One of the main advantages of CNC machining is its ability to achieve high precision; however, it often generates material waste during the process. By starting with a 3D-printed base, you minimize raw material usage, reducing waste before the CNC process begins. This ensures that only minimal finishing is needed, making it a more sustainable option.

Certain materials used in 3D printing, such as resins or polymers, may not have the same strength as metals or harder alloys used in CNC machining. With hybrid manufacturing, you can print complex structures in lightweight materials and then reinforce specific parts through machining for added durability, ensuring a high-performance end product.

By combining additive and subtractive techniques, hybrid manufacturing can cut down on costs associated with tooling, labor, and waste. Manufacturers can achieve more in fewer steps, leading to significant cost savings that accumulate across production cycles. Additionally, this approach allows for more accurate customization, reducing the need for rework.

Applications of Hybrid Manufacturing

Hybrid manufacturing has diverse applications across industries. Whether it’s in automotive, aerospace, or medical device manufacturing, the synergy between CNC machining and 3D printing creates parts with improved accuracy, durability, and complexity. From functional prototypes to fully finished parts, hybrid solutions are becoming a go-to method for manufacturers looking to optimize production.

Conclusion:

Hybrid manufacturing is revolutionizing how products are designed and manufactured. By leveraging the best of both CNC machining and 3D printing, companies can streamline production, improve quality, and reduce costs. As a forward-thinking business, Innovix Pro integrates these technologies to provide cutting-edge solutions that accelerate your time-to-market while maintaining exceptional standards.

By highlighting the advantages and applications of hybrid manufacturing, Innovix Pro helps businesses find more efficient paths to market. Whether you’re looking to speed up production or reduce costs, hybrid manufacturing is key to staying competitive in today’s evolving landscape.