Rapid Prototyping: How to Reduce Time-to-Market for Your Products

In today’s competitive business environment, reducing time-to-market is crucial for companies aiming to stay ahead. Leveraging rapid prototyping technologies like 3D printing and CNC machining, businesses can speed up product development and achieve faster market entry.

This article explores the strategies and technologies that help businesses accelerate product development and minimize delays.

What is Rapid Prototyping?

Rapid prototyping is a method used to quickly produce physical prototypes using advanced technologies. It allows companies to test, refine, and finalize product designs before full-scale production. At Innovix Pro, we specialize in innovative rapid prototyping services, offering businesses a faster route to market success.

Strategies to Reduce Time-to-Market

One key approach in rapid prototyping is iterative development. Instead of waiting until the final stage to identify issues, iterative processes enable quick feedback and adjustments at every stage. By constantly refining designs, businesses avoid costly delays and achieve faster results.

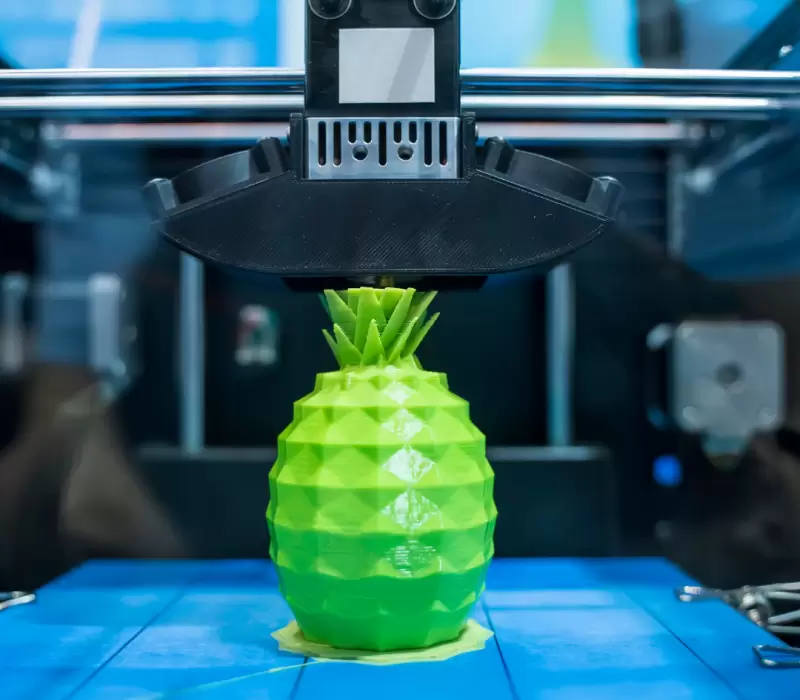

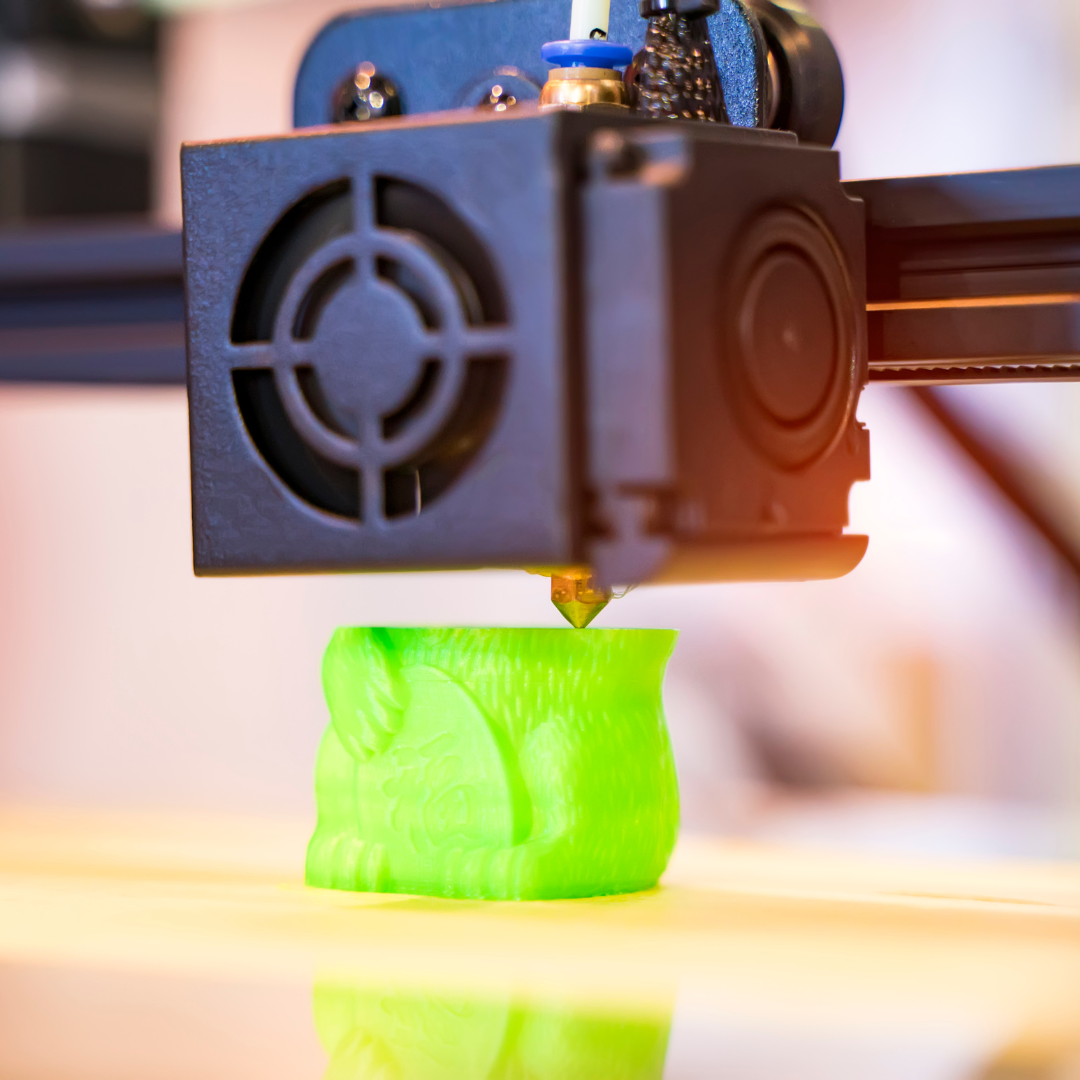

3D printing is one of the most powerful tools in rapid prototyping. This technology allows businesses to create detailed prototypes within hours, significantly cutting down the time spent on traditional methods. From plastic to metal, 3D printing at Innovix Pro offers flexibility, fast iteration, and a cost-effective solution for companies looking to speed up product testing and validation.

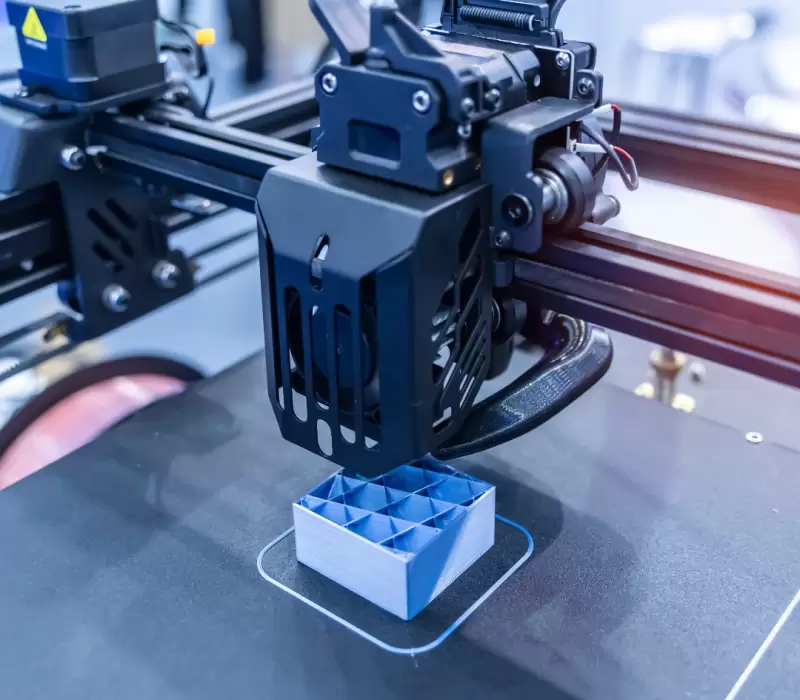

For industries requiring high-precision prototypes, CNC machining provides the accuracy needed for functional testing. This technique is perfect for producing prototypes that must mimic final production quality and performance, especially in sectors like aerospace, automotive, and healthcare.

Cloud-based collaboration platforms allow design teams to work together in real-time. By leveraging tools like CAD software, businesses ensure all stakeholders are aligned, reducing bottlenecks and enabling faster approvals.

Utilizing virtual simulation tools can reduce the need for multiple physical prototypes. By predicting how designs will behave under different conditions, businesses can identify and correct issues before production, saving valuable time and resources.

Technologies Driving Rapid Prototyping

- Additive Manufacturing (3D Printing): Ideal for creating fast, detailed prototypes for design verification.

- CNC Machining: Suitable for high-precision prototypes that require functional testing.

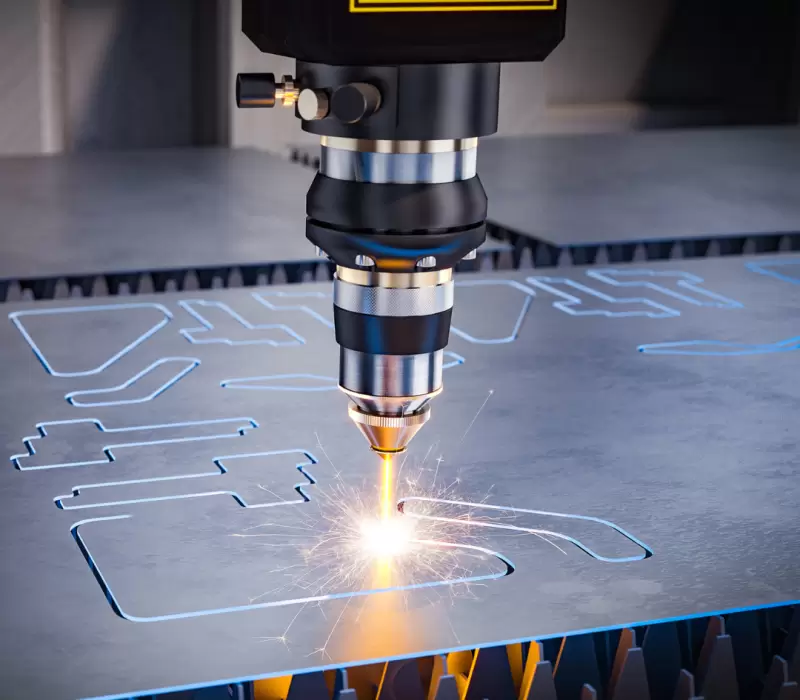

- Laser Cutting: Effective for prototyping intricate designs in flat materials.

- CAD and Simulation Software: Facilitates virtual testing, helping businesses optimize designs without physical trials.

Hybrid manufacturing, which combines traditional and additive techniques, is gaining popularity. This approach leverages the strengths of both methods—melding the precision and reliability of conventional manufacturing with the flexibility and innovation of 3D printing.

It’s particularly beneficial in industries like aerospace and defense, where components need to meet exacting standards for safety and performance.

One of the most disruptive trends in 3D printing is its potential to decentralize manufacturing. Instead of relying on centralized factories, companies can now produce parts on demand, closer to their end-users. This reduces shipping costs and delivery times and enables greater customization and responsiveness to market changes.

Industries from automotive to consumer goods are exploring how decentralized production could reshape global supply chains.

Benefits of Rapid Prototyping for Businesses

Faster Product Iteration

Rapid prototyping enables multiple iterations, ensuring quicker improvements to product design.

Cost Savings

Early identification of design flaws minimizes expensive changes later in the production cycle.

Flexibility

Quick adjustments help businesses stay agile.

Reduced Risk

Thorough testing of prototypes mitigates the risks of launching flawed products.

Challenges on the Horizon

Despite its bright future, 3D printing still faces hurdles. Quality control, material development, and intellectual property protection remain significant challenges. Additionally, scaling production to meet industrial demands without sacrificing quality is an ongoing struggle that will require new solutions and innovations.

Conclusion:

In a landscape where speed is essential, rapid prototyping offers a proven pathway to expedite product development. By adopting effective strategies and leveraging advanced technologies like 3D printing and CNC machining, businesses can minimize delays and enhance collaboration. Embracing these innovations will ensure companies remain competitive in an ever-evolving market.

Are you ready to accelerate your product development? Partner with Innovix Pro to discover how our rapid prototyping solutions can help you achieve faster time-to-market and drive success in your industry!

Rapid Prototyping: How to Reduce Time-to-Market for Your Products

In today’s world, speed is everything. The ability to bring a new product to market quickly can make the difference between being a market leader and playing catch-up. When it comes to getting ahead, reducing time-to-market has become crucial for companies of all sizes. One powerful way to achieve this is through rapid prototyping.

This approach helps businesses accelerate their product development process by utilizing innovative technologies and methodologies that eliminate delays, improve efficiency, and help launch products faster. Let’s dive into how rapid prototyping can give you a competitive edge.

What Exactly is Rapid Prototyping?

Think of rapid prototyping as the fast track to innovation. It’s all about creating a preliminary version of a product quickly—whether it’s a physical or digital model—so that it can be tested and refined without waiting for the entire development process to be completed. This method allows teams to evaluate design concepts, functionality, and usability early on. The quicker you can identify issues, gather feedback, and make improvements, the faster you can get your product to market. In essence, rapid prototyping is about faster iterations and smarter decision-making.

Proven Strategies to Speed Up Product Development

3D printing has revolutionized the way prototypes are developed. It enables businesses to create tangible prototypes in hours or days, rather than weeks. Using materials ranging from plastics and metals to advanced composites, you can quickly produce prototypes, test them, and make necessary adjustments.

The more iterations you can achieve in a shorter time frame, the better your final product will be. By closing the gap between design and prototype, 3D printing ensures you catch design flaws early, cutting down on expensive revisions later in the process.

Adopting agile methodologies can be a game-changer for speeding up product development. Agile focuses on flexibility, collaboration, and iterative progress. By breaking the development process into smaller, manageable tasks and working in short, focused sprints, teams can quickly build prototypes, gather feedback, and make the necessary adjustments.

This approach reduces delays and enhances responsiveness to changing requirements or unexpected challenges. Agile also encourages cross-functional collaboration, bringing together designers, engineers, and marketers to align objectives and accelerate decision-making.

Virtual prototyping and simulation tools allow you to create and test digital versions of your product before investing in physical prototypes. With tools like Computer-Aided Design (CAD) and Finite Element Analysis (FEA), you can analyze and optimize your product’s performance early on.

This approach saves valuable time, as multiple iterations can be tested quickly without the need for physical materials or labor-intensive processes. By identifying potential issues in a virtual environment, you reduce the need for numerous physical prototypes, thereby speeding up the entire development cycle.

Design thinking is all about putting the user at the heart of the design process. By understanding your customers’ needs and pain points, you can develop prototypes that align with their expectations from the get-go.

Rapid prototyping allows for continuous refinement based on user feedback, reducing the risk of costly changes later on. This approach encourages creative problem-solving and innovation, helping you develop efficient solutions faster and more effectively.

Automation can significantly accelerate the testing and quality assurance phases. By automating repetitive tasks such as functionality checks and performance evaluations, you can quickly identify defects and ensure your product meets all necessary standards.

Automation not only reduces manual labor but also improves accuracy and consistency, allowing teams to focus on more complex aspects of development. Continuous testing throughout the process means you catch issues early, avoiding the need for extensive rework later.

Key Technologies That Drive Rapid Prototyping

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is at the heart of rapid prototyping. It enables you to quickly create complex, high-quality prototypes without investing in expensive molds or tooling.

With the flexibility to use various materials and print multi-material components in a single process, 3D printing offers speed and versatility like never before.

Digital Twins and Simulation Software

Digital twins—virtual replicas of physical products—allow you to simulate real-world conditions and predict performance. By using digital twins, you can thoroughly test and optimize your prototype before moving to the physical modeling stage.

This technology helps catch potential issues early on, reducing the number of physical prototypes needed, saving time, and cutting costs.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR are emerging as powerful tools in rapid prototyping. They provide a way to visualize and interact with digital prototypes in a realistic context. By using these immersive technologies, teams can better understand design choices, quickly spot flaws, and gather feedback faster.

This reduces the need for multiple physical models and enhances communication among stakeholders, speeding up the overall development process.

Collaborative Cloud Platforms

Cloud-based collaboration tools make it easier for team members to communicate and share data in real time, no matter where they are.

By using a centralized platform for project management, design files, and feedback, these tools facilitate faster decision-making and reduce delays due to miscommunication or data silos.

How Innovix Pro Can Help You Accelerate Product Development

At Innovix Pro, we specialize in rapid prototyping solutions that help businesses reduce time-to-market. By leveraging the latest technologies and industry best practices, we offer end-to-end services to streamline your product development from concept to launch. Whether it’s 3D printing, digital prototyping, or agile methodologies, we tailor our approach to meet your specific needs and objectives.

Our team at Innovix Pro is dedicated to helping you minimize risks, lower costs, and bring your products to market faster, ensuring you stay ahead in today’s highly competitive landscape.

Final Thoughts

When speed is the name of the game, rapid prototyping is your best bet for faster product development. By adopting agile strategies, utilizing digital tools, and embracing advanced technologies like 3D printing, businesses can reduce delays, enhance collaboration, and accelerate their time-to-market. The key is to create, test, and iterate quickly while keeping your customers’ needs at the center of every decision.

Ready to boost your product development speed? Partner with Innovix Pro today, and let’s bring your ideas to life faster than ever before. We’re here to help you stay ahead of the curve and win in today’s fast-paced market.