The Future of 3D Printing: Emerging Technologies and Trends to Watch

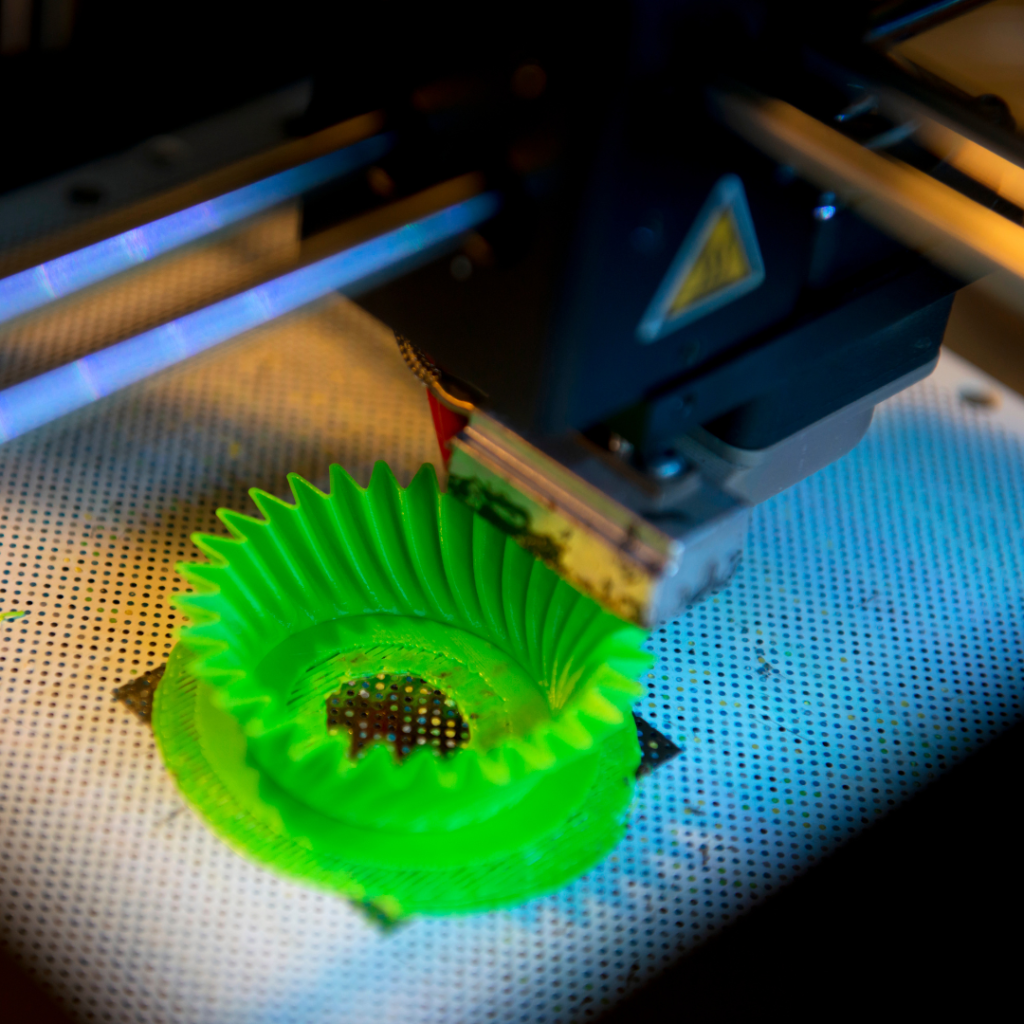

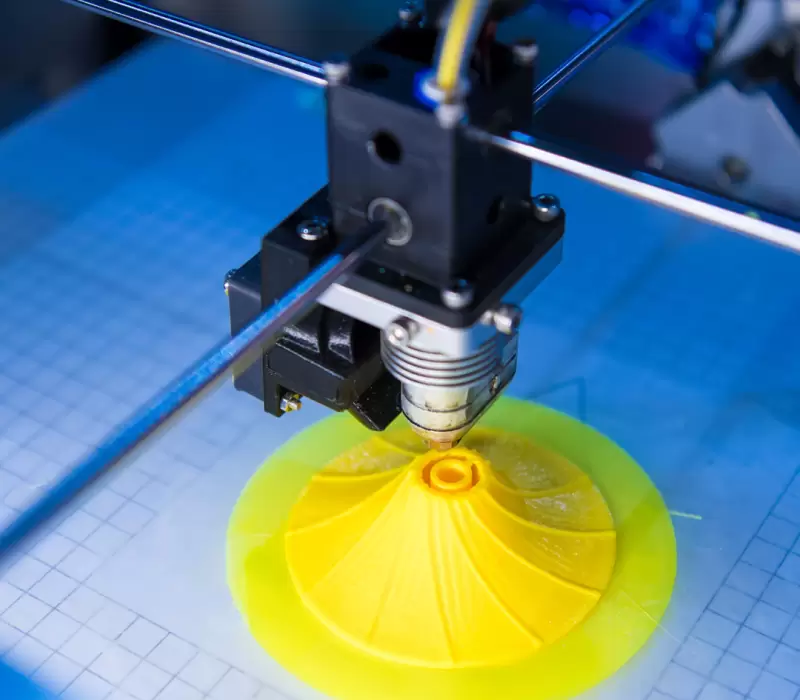

The world of manufacturing is changing rapidly, thanks to the evolution of 3D printing technology. This innovative approach is moving beyond its initial phase, becoming a powerful tool for enhancing production, cutting costs, and supporting sustainable practices.

At Innovix Pro, we're closely following the latest technologies and trends in 3D printing that are likely to shape its future.

The Current Landscape of 3D Printing

3D printing, also known as additive manufacturing, has come a long way from being a niche technology used primarily for prototypes. Today, it’s recognized as a valuable manufacturing solution across a wide range of industries, from aerospace and healthcare to automotive and fashion. Yet, even with its rapid growth, 3D printing still represents less than 1% of the global manufacturing market—a clear indication of its untapped potential.

Key Innovations in 3D Printing

One of the most exciting aspects of 3D printing is the expansion of materials it can work with. While plastic was the go-to material in the early days, we’re now seeing a surge in the use of metals, ceramics, and even biodegradable substances. This variety allows manufacturers to create stronger, more specialized components tailored to the unique needs of different industries.

For example, recent developments have introduced biocompatible materials for medical implants, carbon fiber composites for lightweight parts, and food-grade materials for creating edible products.

Materials like graphene, known for its extraordinary strength and conductivity, are also being incorporated into 3D printing processes. This integration opens up new possibilities for producing durable, high-performance components. Additionally, advancements in flexible, multi-material printing are enabling the creation of complex assemblies in a single step, minimizing waste and speeding up production.

3D printing is no longer just for small-scale production and prototypes. New technologies, like Continuous Liquid Interface Production (CLIP), high-speed sintering (HSS), and multi-laser systems, are dramatically increasing production speeds and reducing costs.

These advancements make it feasible to use 3D printing for larger production runs, challenging the traditional boundaries of manufacturing and supply chain management.

The marriage of 3D printing with Industry 4.0 technologies—such as IoT, AI, and automation—is creating smarter manufacturing environments. These “smart factories” are able to monitor and optimize production processes in real-time, improving efficiency and minimizing waste.

AI-driven design tools allow for the creation of intricate geometries that were once impossible or too expensive to produce using conventional methods, while automation further enhances the overall productivity of 3D printing.

With sustainability becoming a priority for many businesses, 3D printing offers some compelling benefits. Unlike traditional methods that remove material to create parts (and often result in waste), additive manufacturing uses only the amount of material needed. This approach significantly reduces waste and supports more sustainable production practices. New trends are emerging around the use of recycled materials, bio-based filaments, and other eco-friendly alternatives, making 3D printing even greener.

Plus, 3D printing can help reduce the carbon footprint of manufacturing by enabling localized production, cutting down on the need for long-distance transportation and the emissions that come with it.

3D printing’s impact on healthcare is one of its most promising developments. It’s already being used to create custom prosthetics, implants, and even bioprinted tissues and organs, revolutionizing patient care. With the ability to produce patient-specific devices, medical professionals can offer treatments that are more effective and better tailored to individual needs.

Researchers are pushing the envelope further, exploring the potential for printing fully functional organs, which could revolutionize the field of transplant medicine.

Hybrid manufacturing, which combines traditional and additive techniques, is gaining popularity. This approach leverages the strengths of both methods—melding the precision and reliability of conventional manufacturing with the flexibility and innovation of 3D printing.

It’s particularly beneficial in industries like aerospace and defense, where components need to meet exacting standards for safety and performance.

One of the most disruptive trends in 3D printing is its potential to decentralize manufacturing. Instead of relying on centralized factories, companies can now produce parts on demand, closer to their end-users. This reduces shipping costs and delivery times and enables greater customization and responsiveness to market changes.

Industries from automotive to consumer goods are exploring how decentralized production could reshape global supply chains.

Trends to Watch

On-Demand Production

3D printing enables manufacturers to produce parts exactly when they need them, reducing the need for large inventories.

This flexibility cuts storage costs and makes supply chains more agile, allowing businesses to adapt quickly to shifting market demands.

Customization and Personalization

With 3D printing, manufacturers can offer a high degree of customization, catering to specific consumer needs and preferences.

This is particularly useful in sectors like healthcare, where personalized medical devices and prosthetics can be produced more efficiently and affordably.

Expansion into New Industries

While 3D printing has already made significant inroads in established industries, its potential applications are vast.

New fields like construction and bioprinting are starting to tap into its capabilities, with initiatives such as 3D-printed homes and organ printing generating excitement and interest.

Challenges on the Horizon

Despite its bright future, 3D printing still faces hurdles. Quality control, material development, and intellectual property protection remain significant challenges. Additionally, scaling production to meet industrial demands without sacrificing quality is an ongoing struggle that will require new solutions and innovations.

Conclusion: A New Era for Manufacturing

The future of 3D printing looks incredibly promising, with ongoing advancements poised to revolutionize how we manufacture goods. As the technology becomes more ingrained in supply chains and across various industries, its impact will continue to grow.

Whether it’s making production more efficient, enabling sustainable practices, or unlocking new possibilities in healthcare, 3D printing is set to play a key role in shaping the future of manufacturing. At Innovix Pro, we are dedicated to staying ahead of these trends and embracing the innovations that will define the future of our industry.

Are you ready to see how 3D printing can transform your business? Keep an eye on this space for more updates on the latest trends and breakthroughs in this exciting field!