Top 5 Materials for High-Performance 3D Printing

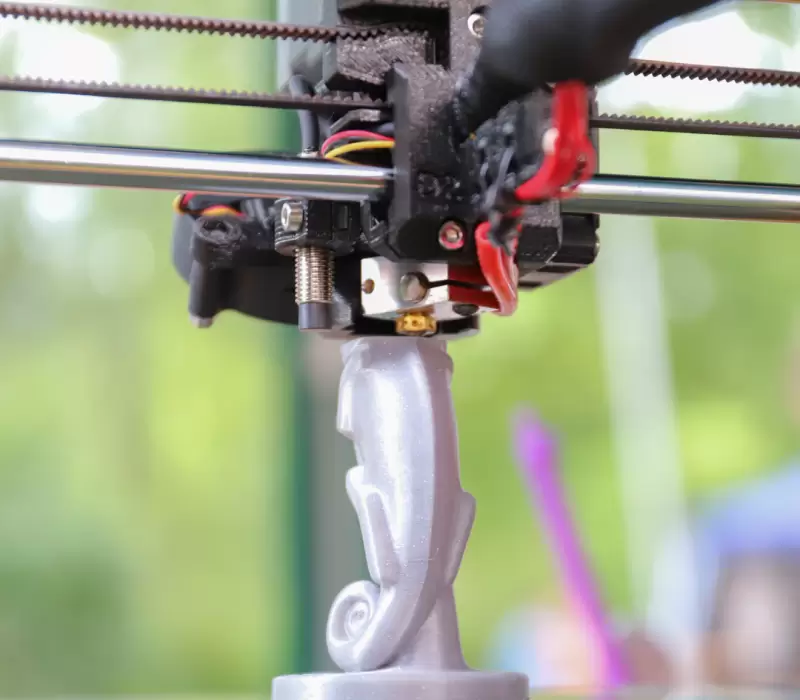

3D printing has evolved significantly over the past decade, offering a growing variety of materials tailored for different applications. Whether for prototypes or production parts, selecting the right material can significantly influence performance, durability, and functionality.

In this blog, we will explore the top 5 materials used in high-performance 3D printing, highlighting their unique properties and applications.

Nylon is a widely used material in 3D printing due to its excellent mechanical properties and durability. Known for its toughness, flexibility, and resistance to abrasion, nylon is ideal for functional prototypes and end-use parts that require strength and wear resistance.

Benefits:

- High durability and impact resistance

- Good chemical and moisture resistance

- Flexible, making it suitable for parts requiring movement

Applications:

- Automotive parts

- Functional prototypes

- Gears and mechanical components

Nylon is particularly popular in industries that demand robust parts, such as automotive and consumer products.

PEEK is a high-performance polymer that offers outstanding mechanical properties, thermal stability, and chemical resistance. It is often used in demanding applications where high heat and chemical exposure are concerns.

Benefits:

- Extremely high heat resistance (up to 260°C)

- Excellent mechanical properties

- High resistance to chemicals and radiation

Applications:

- Aerospace components

- Medical implants

- Automotive parts

Due to its high strength-to-weight ratio and ability to withstand extreme environments, PEEK is favored in aerospace and medical fields, including spinal implants and engine parts.

Carbon fiber composites are increasingly popular in high-performance 3D printing because they combine the lightweight properties of carbon fiber with the strength of a base polymer. These materials are typically used in critical applications where the strength-to-weight ratio is essential.

Benefits:

- Lightweight with high stiffness

- Excellent strength-to-weight ratio

- Suitable for functional parts under stress

Applications:

- Drone components

- Automotive and aerospace parts

- Sporting goods

Carbon fiber composites are used to create parts that need to be strong yet lightweight, such as drone frames, prosthetics, and racing car components.

Metal 3D printing, also known as metal additive manufacturing, uses metal powders like titanium, aluminum, and stainless steel to produce strong, durable parts with precise geometries. Metal alloys are crucial in industries that require parts with high mechanical strength and temperature resistance.

Benefits:

- High strength and durability

- Excellent thermal and electrical conductivity

- Corrosion resistance (specific to stainless steel)

Applications:

- Aerospace components

- Medical implants (e.g., titanium prosthetics)

- High-performance automotive parts

The use of metal alloys in 3D printing is transforming industries like aerospace and medical sectors by enabling the production of customized, high-strength components.

TPU is a flexible and elastic material that offers excellent abrasion resistance, making it ideal for parts requiring flexibility and shock absorption. Its versatility and durability make it a popular choice for both consumer goods and industrial applications.

Benefits:

- Elastic and flexible

- High resistance to abrasion and impact

- Good chemical resistance

Applications:

- Footwear (custom soles)

- Flexible prototypes

- Wearable devices

TPU’s flexibility is ideal for industries like consumer electronics and footwear, where products need to be durable yet comfortable.

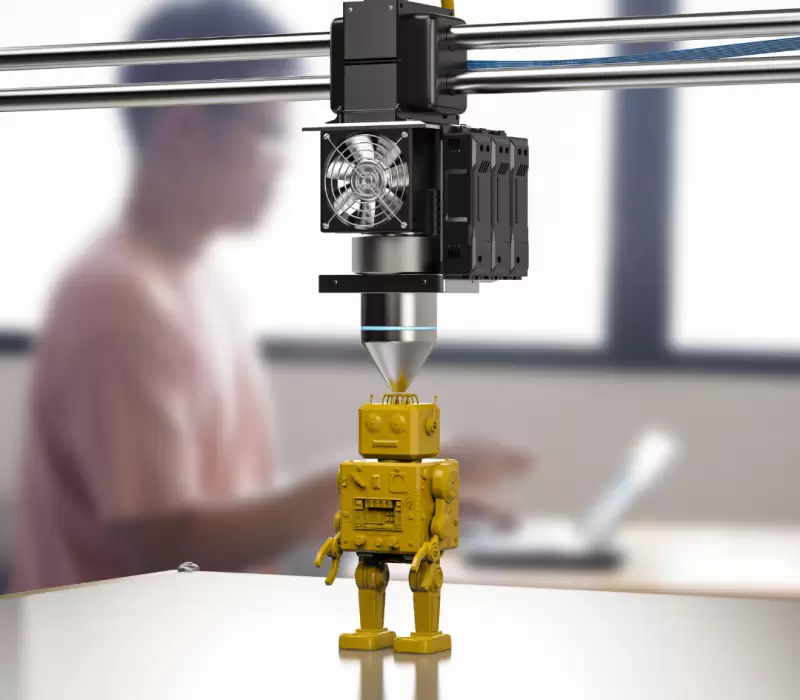

Conclusion:

Selecting the right material can elevate your 3D printing projects, delivering better functionality, strength, and durability. Whether you need a lightweight yet strong part, a heat-resistant component, or something flexible and durable, these top 5 materials can help you achieve your production goals. At Innovix Pro, we specialize in high-performance 3D printing, guiding you to choose the best material for your specific project needs.

Contact us today to learn more about our 3D printing services and how we can help streamline your product development process with the right material choices!